Historic partnership: Australian lunar base camp builder teams up with UNSW

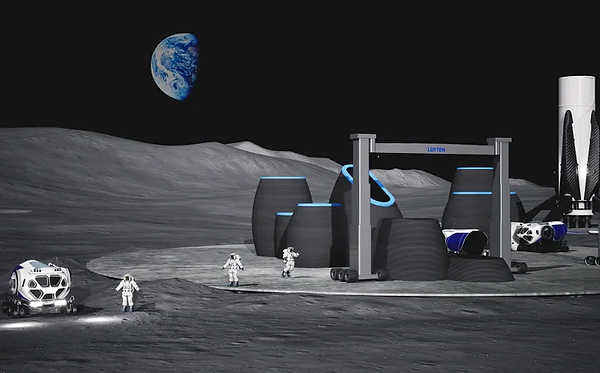

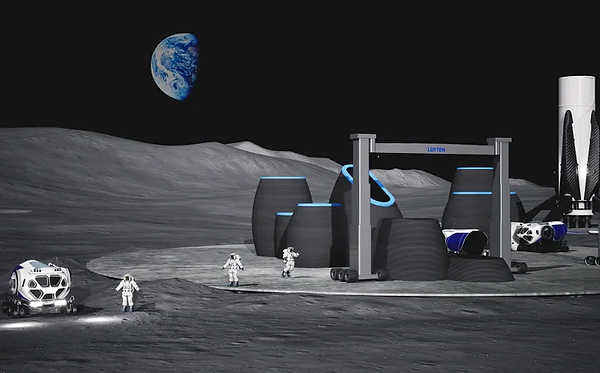

Cutting-edge Australian 3D printing building and construction company, Luyten, has signed an historic Memorandum of Understanding (MOU) with the University of New South Wales (UNSW) to fast-track development and delivery of 3D printing technology to build structures on the moon.

The MOU will see UNSW and Luyten working together to develop, test and implement technology to deliver lunar building solutions.

“We are absolutely delighted and extremely honoured to be partnering with UNSW to make building on the moon possible. UNSW is renowned for its academic leadership and world class research and we couldn’t be more pleased to be working together,” Luyten cofounder and CEO, Ahmed Mahil said.

“Our combined expertise and passion for innovative and exceptional building outcomes involving a range of intertwined disciplines will help the human race to expedite colonisation of the moon and other planets. Our partnership will solidify Australia’s leading role in the world’s fast developing space economy.”

Since launching in 2020, Luyten’s mission has been to make construction easier and more sustainable across a broad range of industries by reducing the time and cost to build, the amount of construction waste generated, and the impact of build activities on the surrounding environment.

Luyten’s cutting-edge 3D printing and additive technologies have become a world-wide success story as companies across the globe scramble to purchase its printers. In response to global demand, Luyten is now expanding the scope of its technology use to moon building.

“When we developed our groundbreaking 3D concrete printers, we thought we would be solving building and construction issues across the world – but with discussions currently taking place with people across the space industry we are now looking at solving building and construction issues on the moon,” Luyten cofounder and CEO, Ahmed Mahil said.

“As a result, we have commissioned Project Meeka. Meeka means moon in some of Australia’s First Nations languages. Our lunar work is advanced and now at a stage where it is fine tuning and testing the types of materials and designs needed for construction purposes on the surface of the moon.

“The 3D printer we have developed to undertake construction on the moon is called Platypus Galacticas.

“This printer is agile and transformable. It can transform from a size of 3m x 4m in height and width to 9m x 12m in height and width, capable of producing a structure of up to 9m x 12m in height and length. The printer can be set up in less than 30 minutes.

“We have designed the printer for compactness using light weight composites for its structure and robotic transforming technology, making it ideal for space transportation purposes.”

According to Associate Professor Matthias Hank Haeusler, the Discipline Director of the Bachelor of Computational Design (CoDe) at the Australian School of Architecture + Design (Built Environment), UNSW, the MOU will ensure the country’s greatest minds are involved in capacity building for lunar construction.

“With Computational Design one has a method to design protective shells for habitats on the moon – with a foremost consideration on requirements for human habitat in mind. Computational Design allows to feed in scientific knowledge on how to protect humans from solar and cosmic radiation into a script that generates a shelter with the required 80 plus centimetres of solid material while optimising the structure towards the print process,” Associate Professor Haeusler said.

You must be logged in to post a comment.